“The control and reduction of greenhouse gas emissions, along with sustainable growth, are key priorities for companies. Having “partners” who can help in decision-making and implementing solutions in a field that is still not widely mastered is essential. CoLAB Net4CO2 met the company’s expectations and needs for the near future. In addition to their expertise in technological matters, they demonstrated innovation, flexibility, and professionalism—qualities that are fundamental to their approach and the solutions they deliver.”

Rita Carreira | Plant Manager

Project Duration: 2024

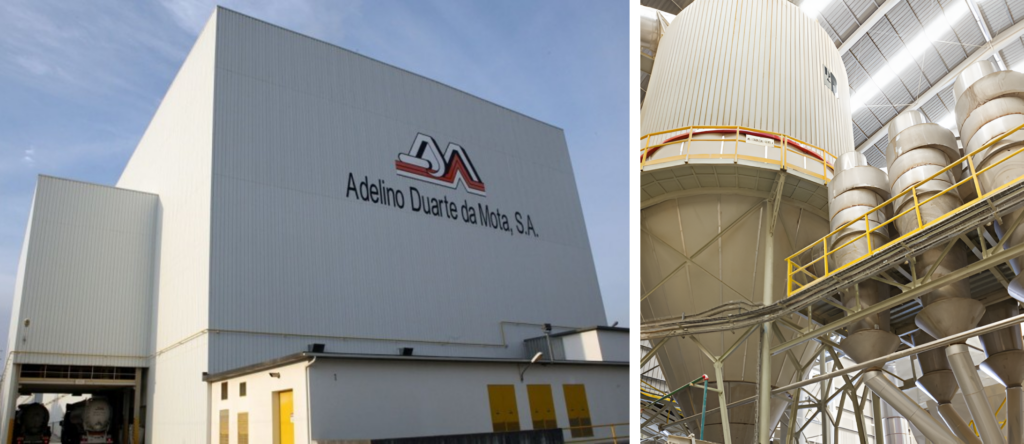

Client

Project Description

•Identifying the most effective post-combustion carbon capture technologies tailored to ADM’s specific production processes, the largest national producer and supplier of ceramic paste, ensuring high capture efficiency and seamless integration into existing operations.

•Exploring waste heat recovery options to improve energy efficiency and investigating water recovery technologies to extract and reuse water from flue gases, contributing to a more circular production model.

•Assessing viable CO₂ valorization strategies, including potential industrial applications, mineralization, or conversion into value-added products to maximize sustainability benefits.

•Conducting a comprehensive evaluation of the proposed solutions, including cost-benefit analysis, feasibility studies, and Life Cycle Assessment (LCA) to ensure long-term viability and alignment with regulatory frameworks.

Main Outcomes

•Facility Assessment and Emissions Mapping: Detailed assessment of the ADM facility, including infrastructure, operational processes, and emissions sources.

•Emissions Data Validation and Optimization: In-depth evaluation of emissions records for each atomizer to detect technical inconsistencies and discrepancies with production data, ensuring accuracy and identifying potential optimization opportunities. Identification and assessment of water and waste heat recovery technologies to reduce natural gas and water consumption. These initiatives aim to maximize energy efficiency, decrease operational costs, and elevate the facility’s sustainability performance.

•Energy and Resource Efficiency Enhancement: Identification and assessment of water and waste heat recovery technologies to reduce natural gas and water consumption. These initiatives aim to maximize energy efficiency, decrease operational costs, and elevate the facility’s sustainability performance.

•Carbon Capture Technology Evaluation: State-of-the-art analysis of CO₂ capture techniques, including supplier evaluation, benchmarking, and ranking to determine the most suitable solutions based on ADM’s specific flue gas composition and process conditions.