Services

We help industries reach carbon neutrality and our facilities can be booked for any R&D purpose related to CCUS

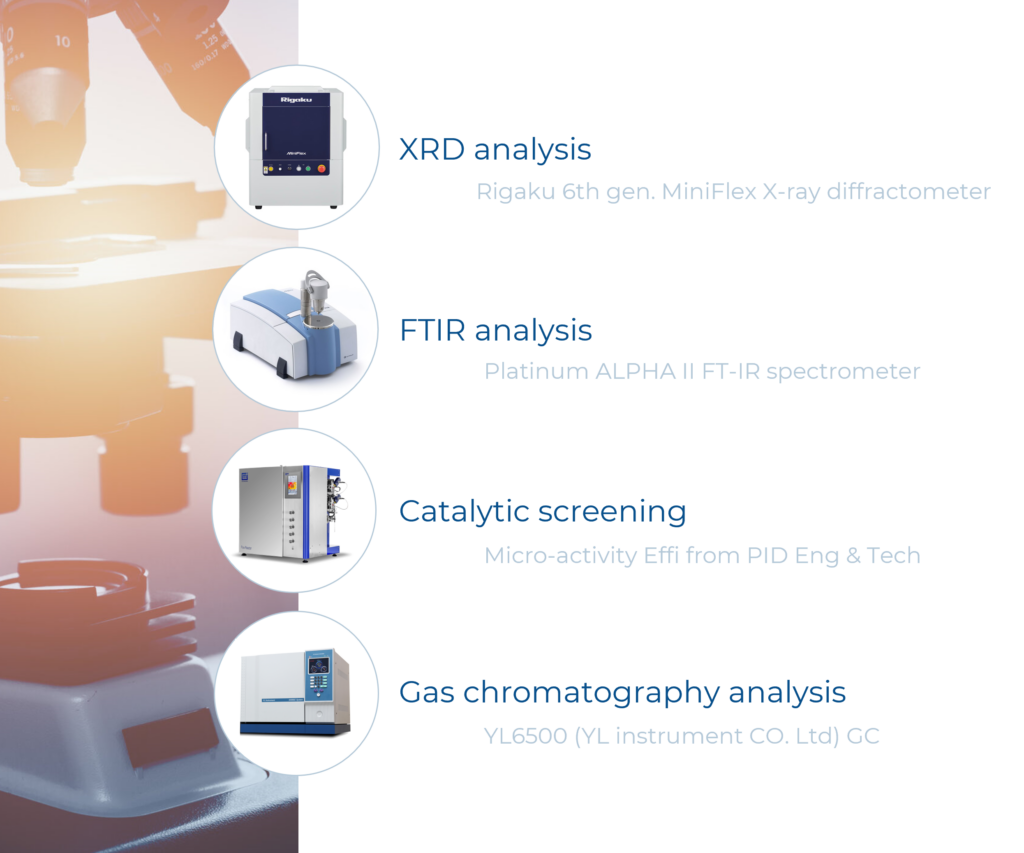

Laboratory Analysis

Characterization of solid and liquid materials for CO2 capture and utilization technology using our facilities

Determination of network parameters, evaluation of crystallinity, identification of phases, among other applications.

Identification of functional groups, study of chemical interactions, analysis of material purity, and degradation.

Study and evaluation of catalytic performance of different materials – catalytic screening and parametric study for assessment of ideal operating parameters.

Provide a technical-scientific report with main results identifying the most promising materials and the ideal operating conditions.

Analysis of liquids and/ or gases with suitable chromatographic columns for permanent gases and hydrocarbons (C2 to C20).

Material characterization and integrity, safety & performance assessment of CO2 capture systems through our external partners

On-site characterization of post-combustion flue gases in terms of CO2 concentration, particulates, heavy metals, etc.

Application of Non-Destructive Testing Techniques – namely ultrasound, induced currents, and computed tomography – in metals, composites and other materials.

Use of monitoring systems with sensors associated with impedance techniques to assess the integrity and maintain reliability, safety and performance in CO2 capture installations.

Advanced characterization of nanomaterials:

Particle size (DLS)

Surface area (BET)

Metals quantification (ICP)

Electronic microscopy (SEM and TEM)

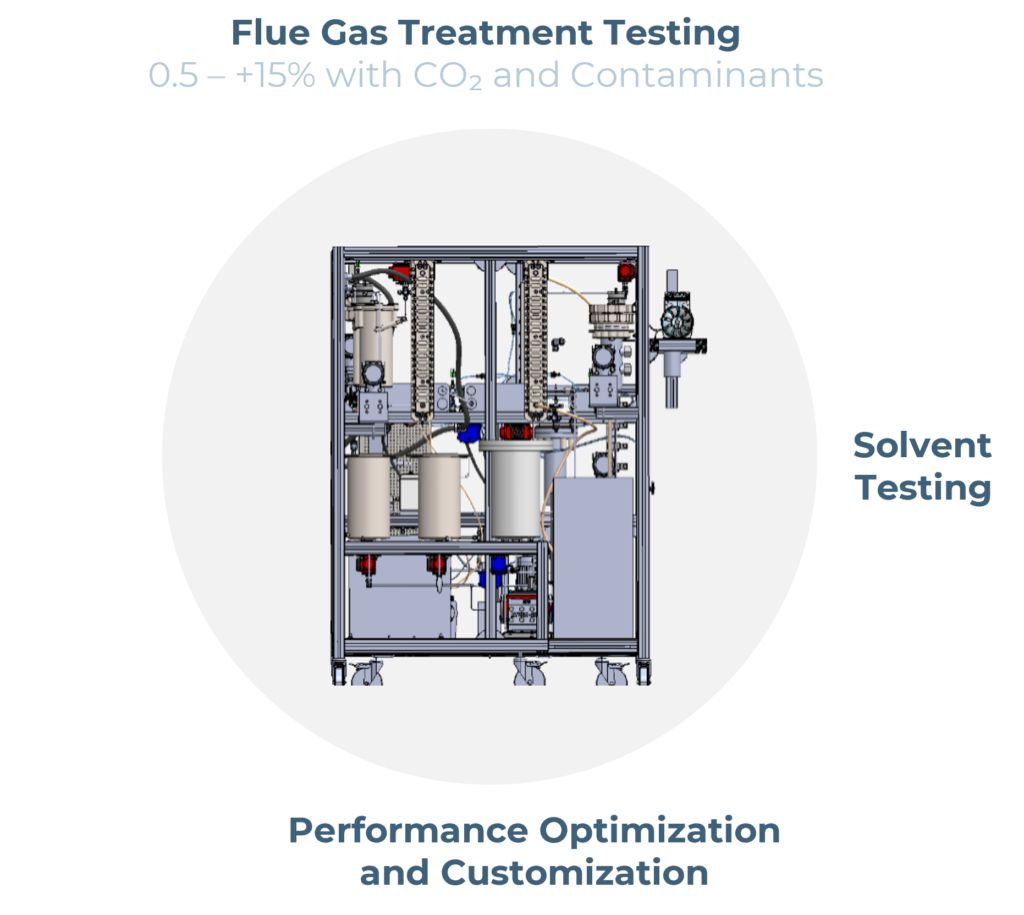

Advanced Lab Testing Solutions

(Starting in Q3 2025)

Explore our Carbon Capture and Utilization unit for solvent and catalyst testing as part of our Laboratory Analysis service.

Test gas samples with varying CO2 concentrations and contaminants, analyzing solvent performance and CO2 capture efficiency in diverse scenarios.

Screen and test alternative solvents, including solid materials, evaluating their thermal and chemical stability for integration into the CO2 capture process.

Optimize CO2 capture performance, scalability, and cost-effectiveness, with system customization and solutions to meet higher technological readiness levels (TRL) for industrial implementation.

Mobile Test Unit

The Mobile Test Unit is designed to efficiently capture CO2 emissions from industrial flue gases and convert it into value-added products

(Starting in Q4 2025)

Net4CO2 offers a Mobile Test Unit (MTU) specifically designed to assist hard-to-abate industries in implementing and testing Carbon Capture and Utilization (CCU) technologies at their operational facilities.

The on-site testing unit for CCU, available for rent, offers hard-to-abate industries a dedicated platform for testing both Net4CO2’s innovative capture and utilization technologies, as well as integrating external technologies for evaluation in the same unit.

With a modular and adaptable design, the demonstrator seamlessly integrates into various industrial settings.

The Mobile Test Unit thereby aims to speed up the transition of hard-to-abate industries toward energy-efficient, low-carbon operations.

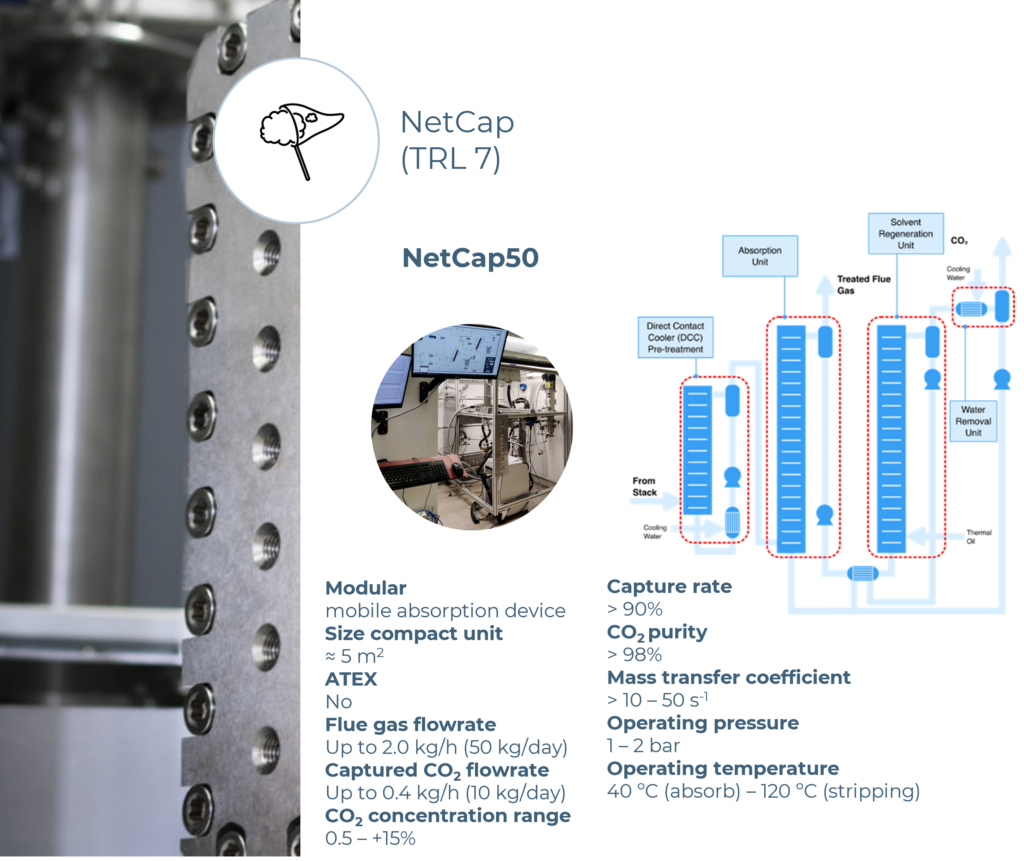

CO2 Capture

The mobile test unit uses NetCap capture technology, effective for flue gases with CO₂ concentrations ranging from 0.5 – 15% and above, offering a significant advantage over conventional commercial technologies, which often struggle to operate efficiently at lower CO₂ concentrations.

Modular mobile absorption device

Unit Footprint ≈ 5 m2

ATEX No

Flue gas flowrate 0.5 – 2.0 kg/h (12 – 50 kg/day)

Captured CO2 flowrate 0.02 – 0.4 kg/h (0.5 – 10 kg/day)

CO2 concentration range 0.5 – +15%

Capture rate > 90%

CO2 purity > 98%

Mass transfer coefficient > 10 – 50 s-1

Operating pressure 1 – 2 bar

Operating temperature 40 ºC (absorb) – 120 ºC (stripping)

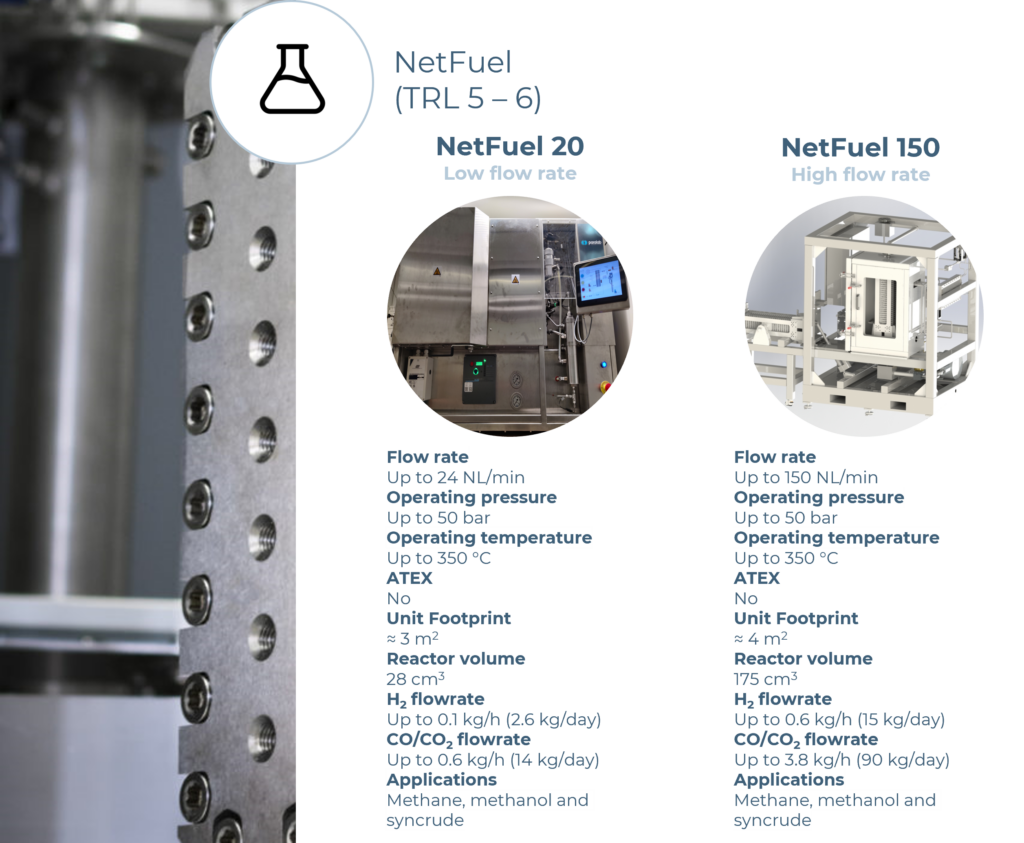

CO2 Utilization

The standard mobile test unit enables the direct conversion of captured CO2 into methane using the NetFuel Utilization technology. On request, other utilization processes can be tested on site, allowing for the mobile unit to convert the captured CO₂ into other valuable products, such as methanol or syncrude.

Modular mobile e-methane production device

Unit Footprint ≈ 3 m2

ATEX No

H2 flowrate 0.054 kg/h (1.30 kg/day)

CO2 flowrate 0.076 kg/h (1.82 kg/day)

H2 : CO2 ratio 4:1

CO2 conversion ~92– 94 %

Methane selectivity 100% (100h)

Productivity 2.4 kg CH4/day

Reactor volume ≈ 30 cm3

Operating pressure 10 – 50 bar

Operating temperature 320 – 350 ºC

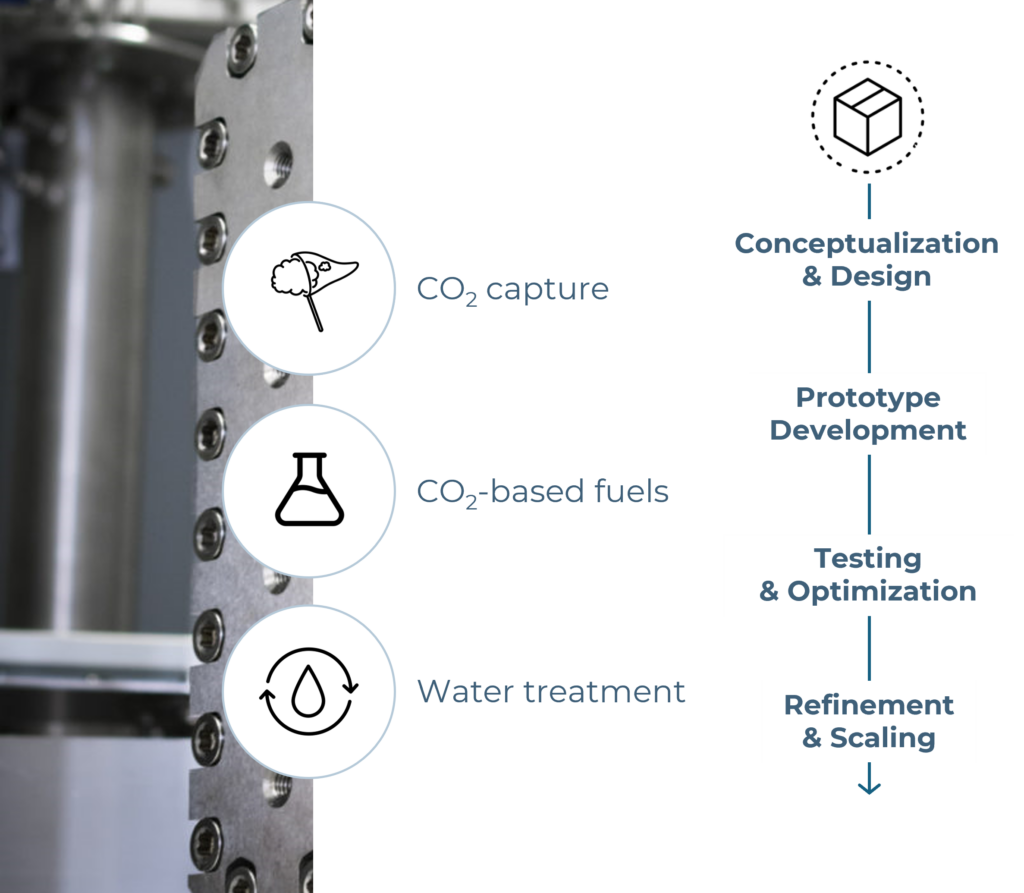

Prototyping

Net4CO2 provides its clients a wide range of prototyping services to support the hard-to-abate industries in advancing CO2 capture, utilization, and related technologies

Define prototype goals and requirements. Simulate conditions and optimize phase equilibrium, temperature, and pressure for efficiency.

Design a prototype using proprietary technology, adjusting reactor plates as needed. Integrate energy recovery to minimize consumption.

Assess functionality, adjust parameters for performance, and evaluate energy efficiency.

Improve design based on data and ensure feasibility for large-scale application.

NetCap Capture System

Our integrated carbon capture prototype can deliver above 90% CO2 capture with unmatched performance compared to conventional amine-based CO2 capture technologies.

Integrated 2-in-1 System Combines CO2, SOx, and NOx removal in a single, efficient unit.

Compact and Modular Design The system is scalable, maintaining equipment size and footprint reduction.

High-Efficiency Structured Absorber Provides mass transfer rates 10 to 50 times higher than conventional amine-based (MEA) CO2 capture technologies.

High-Efficiency for Low CO2 Concentrations Flue Gases Validated with industrial gases with CO2 concentration between 0.5% – 15% from the ceramic and glass industries.

High CO₂ Capture Performance Achieves at least 90% CO2 capture with 98 – 99% CO2 purity.

NetFuel Utilization System

We develop diverse prototypes for CO2-based fuels which can operate in different modes, producing methane, methanol and syncrude.

Compact and Modular Design Seamless scalability and modularity.

Intensified Reaction Engineering Superior mass and heat transfer rates, enabling high throughput efficiency.

Integrated 3-in-1 System Capable of producing e-methane, e-methanol and e-syncrude, all in one unit.

Adaptability and Versatility Its design allows to operate with CO, CO2 and its mixtures, allowing higher experimental customization.

Fully Automated Unit The fully automated unit allows for safe operation even during long duration tests.

Remote operation The unit is remotely operated through an integrated application, allowing monitorization in real time from any location.

AquaMix Unit

Our AquaMix technology optimizes water treatment by reducing CO2 consumption up to 40% whilst using smaller equipment and providing full pH control for greater efficiency.

Reduced Environmental Impact The water pH is controlled though the injection of CO2, reducing the reliance in acids and bases.

Enhanced CO2 Dissolution Efficiency Intensifies the contact between CO2 and Water, increasing dissolution rates.

Significant CO2 Savings Up to 40% reduction of CO2 consumption compared to conventional technologies for water pH control.

Scalability & Industrial Adaptability The modular design allows for seamless integration into various water treatment processes (injection of O2, O3, N2, and others).

Remote Control The unit is remotely operated and fully integrated with an app-based system, enabling real-time monitoring and control from remote locations.

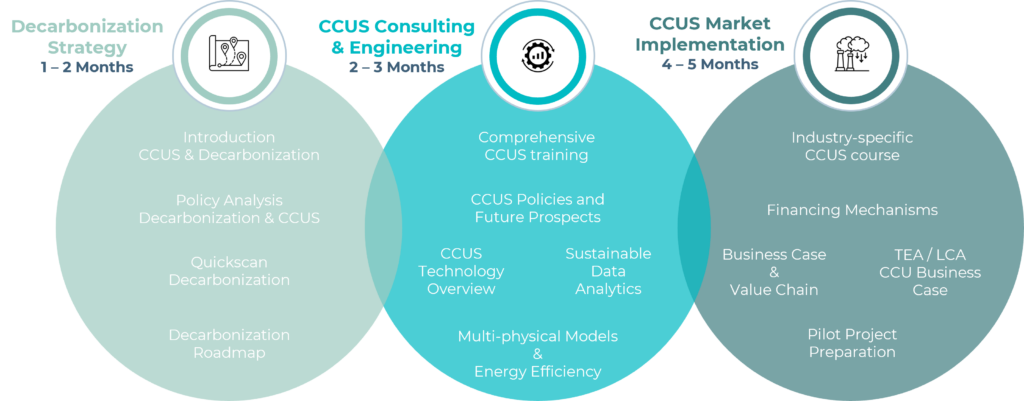

Sustainability Services

Net4CO2 offers modular sustainability service packs for hard-to-abate industries, providing end-to-end support for carbon capture projects—from licensing to certification—ensuring safe and efficient implementation

Net4CO2 provides three modular sustainability service packs, tailored to the needs of diverse stakeholders in hard-to-abate industries, depending on their stage in the sustainability journey

In-depth analysis of sector-specific CCUS policy frameworks and access to EU financing mechanisms.

Decarbonization quick scan assessments tailored to hard-to-abate sectors.

Development of strategic decarbonization and CCUS roadmaps for industrial value chain stakeholders and associations.

Comprehensive assessment and evaluation of carbon capture, utilization, transport and geostorage technologies.

Design of viable CCU business cases for emission-intensive industries.

Techno-Economic Analysis (TEA) and Life Cycle Assessment (LCA) of CCUS business implementation pathways.

Comprehensive support to your carbon capture activities, from licensing to certification, including environmental studies, HSE risk assessments, and ATEX compliance – to ensure your project runs safe and smoothly

Support across licensing and authorization processes (e.g., SIR, SILIAMB).

Constraint analysis and site-specific feasibility assessments.

Evaluation of alternative project implementation areas.

Technical studies focused on environmental regulations and licensing procedures.

Technological risk assessments: PHA, HAZID, HAZOP, QRA, SIL.

Fire safety evaluations and compliance strategies.

ATEX risk assessments and preventive measures.

Guidance through certification processes for ATEX and industrial machinery.

CCUS Training

Net4CO2 developed specialized training programs around CCUS designed to build knowledge and capacity across the hard-to-abate value chain

Introduction and overview of CCUS as a key decarbonization pathway, addressing common misconceptions and showcasing inspiring real-world practices.

A deep dive into all CCUS aspects, including capture, transport, utilization, geological storage, economics, and regulatory frameworks, equipping participants with a holistic understanding of the technology.

Tailored training focused on best international CCUS practices in industries such as cement, ceramics, and chemicals, along with insights into sector-specific policies, financing mechanisms, and CCUS hub opportunities.

Practical aspects of deploying CCUS technologies, from pilot projects to full-scale plants, addressing licensing, HSE requirements, plant design, procurement, integration, and energy efficiency.